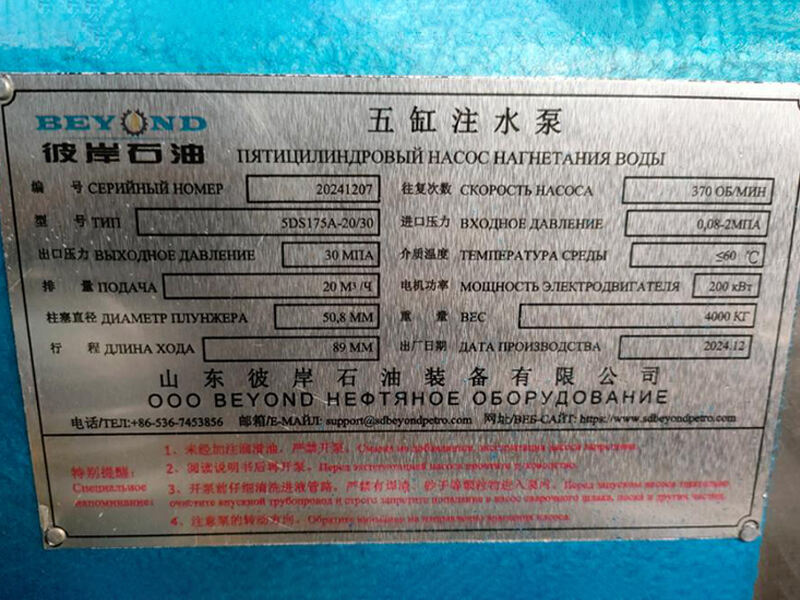

BEYOND Uintuplex Water Injection Pump ready for delivery

A quintuplex water injection pump is a specific type of positive - displacement pump.

Structure and Operation

• Plunger System: It typically has five plungers (hence "quintuplex"). These plungers work in a reciprocating motion. As the plungers move back and forth within their cylinders, they draw water into the pump chamber during the suction stroke and then force the water out under high pressure during the discharge stroke. The coordinated movement of these five plungers helps to provide a more continuous and stable flow of water compared to pumps with fewer plungers.

• Power Transmission: It's usually driven by an electric motor through a power transmission mechanism such as a crankshaft and connecting rods. The motor provides the rotational energy that is converted into the reciprocating motion of the plungers.

Advantages

• High Pressure Generation: It can generate high - pressure water output. This makes it suitable for applications where water needs to be injected into systems with high - pressure resistance, like in deep - well oil injection operations. The high - pressure output helps to overcome the resistance of the formation and ensure efficient water injection.

• Precise Flow Control: The pump can offer precise control over the flow rate of water. The reciprocating action of the plungers allows for accurate metering of the water volume being pumped. This is important in applications where the exact amount of water injection is critical, such as in chemical dosing in water treatment plants or in maintaining specific pressure profiles in oil reservoirs.

• Reliability: With its robust construction and multiple - plunger design, the quintuplex pump is relatively reliable. The presence of five plungers means that if one plunger experiences a problem, the others can continue to operate to a certain extent, reducing the likelihood of a complete pump failure and allowing for maintenance to be scheduled more conveniently.

Applications

• Oil and Gas Industry: It's widely used in the oil and gas sector for water injection into oil reservoirs. By injecting water, the pressure in the reservoir is maintained or enhanced to improve oil recovery rates. The high - pressure and precise - flow capabilities of the quintuplex pump are well - suited for these operations, especially in offshore or deep - well scenarios.

• Industrial Water Treatment: In water treatment plants, it can be used to inject chemicals or to move water through high - pressure filtration systems. For example, it can accurately dose coagulants to help remove impurities from water by facilitating the aggregation of particulate matter.

| Technical parameters | Pump matching accessories | ||||

| Model & Name | 5DS175A-20/30 Quintuplex water injection pump | Name | Model | Qty. | |

| Medium and characteristics | After filtration water | Quintuplex pump | 5DS175A | 1 | |

| Suction pressure (MPa) | 0.08--2 | Pulley | 2 | ||

| Discharge pressure (MPa) | 30 | pulley guard | 1 | ||

| Capacity (m3/h) | 20 | Discharge dampener | 4L / 31.5MPa | 1 | |

| Valve structure | Line valve | Safety relief valve | 1 | ||

| Stroke length ( mm) | 89 | Seismic pressure gauge | 1 | ||

| Plunger diameter (mm) | 50.8 | skid mounted | 1 | ||

| Pump speed (rpm) | 370 | Motor | dIIBT4/IP55 | 1 | |

|

Ex-proof Frequency conversion motor 380V/50Hz |

Model | YBBP-315L--4 | Lubri oil level switch | 1 | |

| speed (rpm) | 1480 | Lubri oil Temp sensor | 1 | ||

| power (kw) | 200 | ||||

| Drive Type | V-belt+ pulley | VFD Box | No-Ex-proof | 1 | |

| Lubrication of power end | forced +cooling | Intake filter | 316Lss | 1 | |

| Dia.of the pump inlet (in) | DN100 flange class 150 | ||||

| Dia.of the pump outlet (mm) | DN50 | ||||

| Dimensions (LxWxH) mm | 2600*1600*1400 | Commissioning spare | 1 set | ||

| Net Wight (KG) | 4000 | Special tools | 1 set | ||

| Material of main parts | |||||

| Pump Frame | HT250 | Liquid cylinder | 316Lss | ||

| Crankshaft | QT800-2 | Plunger | 304+colmonoy6+WC | ||

| Valve | 17-4PH ss | Spring | 316LSS | ||

| Packing | kevlar fiber+PTFE | stuffing box | 316L ss | ||

| bearing shell | 20 High - tin alloys | ||||

After 60 days of intensive production, this water injection pump was successfully completed and all performance indicators met the standards. It is now ready to be shipped to Kazakhstan.

EN

EN

AR

AR

FR

FR

HI

HI

IT

IT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

SL

SL

UK

UK

SQ

SQ

TR

TR

FA

FA

MS

MS

AZ

AZ

KA

KA

MN

MN

KK

KK

UZ

UZ

KY

KY