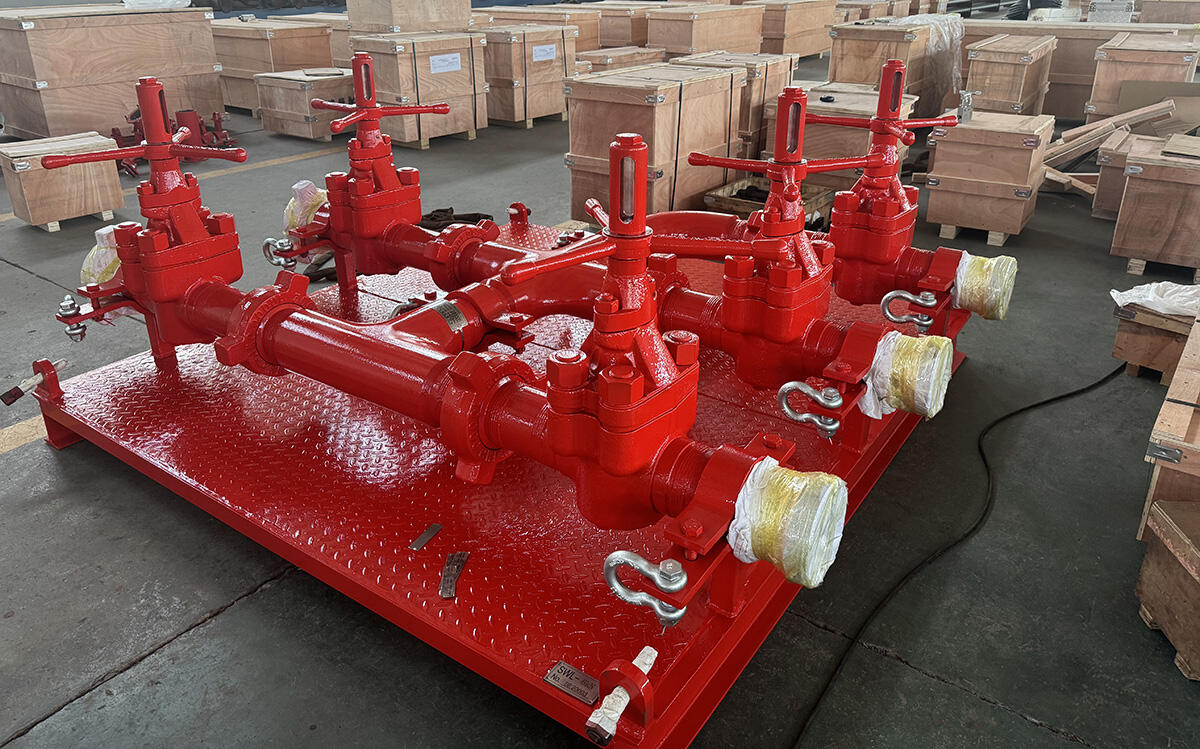

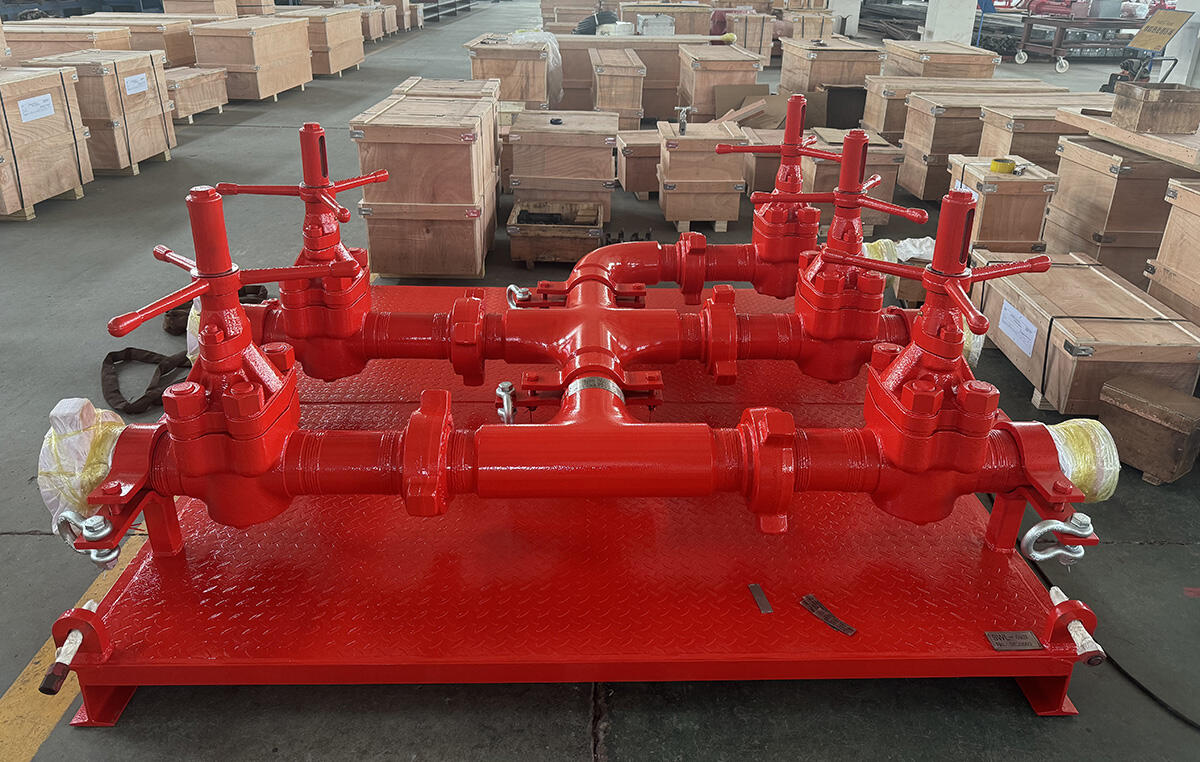

Choke manifold is a necessary device to control the well kick successfully and execute the pressure control technology on oil/gas well in the course of drilling, as it is, the device is adopted to execute new drilling-well's technique of balance pres...

Share

Choke manifold is a necessary device to control the well kick successfully and execute the pressure control technology on oil/gas well in the course of drilling, as it is, the device is adopted to execute new drilling-well's technique of balance pressure, which can prevent the pollution oil-layer, improve the speed of drilling and control blowout effectively. One end of the device connects with the side flange of BOP spool. When BOP closes, it can control the finite pressure from casing by adjusting the choke valve's opening, so balanced drilling can work under minimum pressure-difference.

In case of increase in wellhead pressure, the kill manifold can provide a means of pumping heavy drilling fluid into the well to balance bottom hole pressure so that well kick and blowout can be prevented. In this case, by using blow down lines connected to the kill manifold, the increasing wellhead pressure also can be released directly for bottom hole pressure release, or water and extinguishing agent can be injected into the well using the kill manifold. The check valves on the kill manifold only allow injection of kill fluid or other fluids into the well bore through themselves, but do not allow any back flow to perform the kill operation or other operations.

| Working Pressure | 2,000psi~20,000psi |

| Nominal Bore Diameter | 2 1/16"~ 4 1/16" |

| Working Medium | Petroleum, natural gas, water, mud, gas containing H2S, CO2 |

| Temperature Class | L~U |

| Material Class | AA~HH |

| Product Specification Level | 1~4 |

| Performance Requirement | 1~2 |

BEYOND is a pioneering force in the supply of advanced equipment for the global oil and gas industry. For inquiries or further information, please follow us and contact BEYOND at any time, thank you.