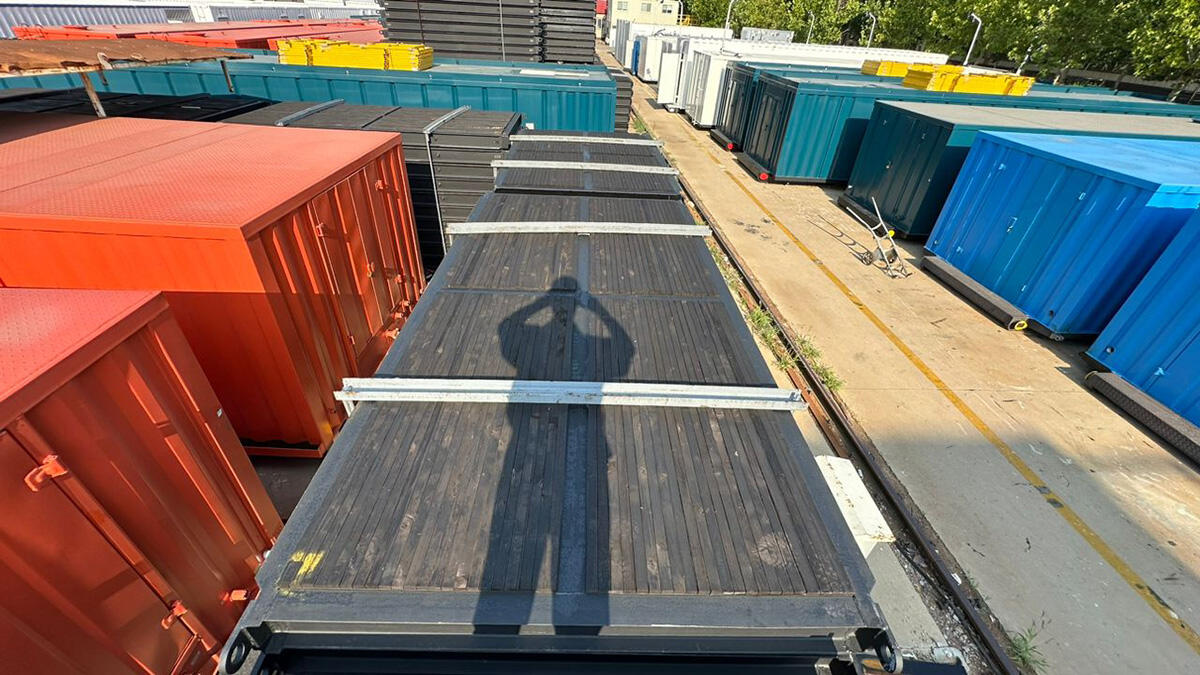

The steel-wood foundation, also known as the rig mat, is a plate-like equipment composed of wood and steel, and is an outdoor ground decoration equipment similar to floor tiles. It enables drilling workers to perform operations in various complex geo...

Share

The steel-wood foundation, also known as the rig mat, is a plate-like equipment composed of wood and steel, and is an outdoor ground decoration equipment similar to floor tiles. It enables drilling workers to perform operations in various complex geographical conditions. For example, when the ground is wet or the land is too unstable during the rainy season, a steel-wood foundation is installed under the land-based oil rig. The main raw materials of steel-wood foundation are: steel and wood

The wood of this product is made of Pinus sylvestris var. mongholica Litv or Pseudotsuga menziesii (Mirb.) Franco, which is hardwood and has strong water resistance. Wood is usually imported from Canada or Russia with Entry Inspection and Quarantine Certificates.

The wood undergoes a series of treatments before being used as a steel-wood foundation,including soaking in wood preservatives and pressurizing in pressurizing device. The main purpose of soaking wood in preservatives is to enhance the durability of wood and its ability to resist fungal decay, insect pests, and marine borers. This treatment method forms a protective layer in the wood to inhibit the growth of decaying microorganisms, thereby increasing the service life of the wood.

Wood Preservative Treatment

Pressurizing wood can improve the anti-corrosion and insect-proof properties of the wood, improve the physical properties of the wood, and extend the service life of the wood.

Improve the anti-corrosion and insect-proof performance: Treating wood by vacuum pressure method can make the preservatives better penetrate into the wood fibers, thereby improving the anti-corrosion and anti-insect properties of the wood and preventing the wood from getting damp and deformed. This method pressurizes the wood in a vacuum tank, allowing the preservative to penetrate deep into every part of the wood,so that the wood can obtain excellent antiseptic and insect repellent properties.

Improved physical properties: wood compression technology is a physical modification method that can significantly increase the density and hardness of wood through pressure treatment,and at the same time significantly improve the dimensional stability of wood.

The steel of this product is Universal Beam I14#/Q235B; The steel is first processed by rust removal and sandblasting before production begins.

After the steel and wood foundation is assembled into a finished product, it will be treated with anti-corrosion treatment such as brushing asphaltpainting, hook marking, product size marking, logo marking, etc., and can be shipped after passing the inspection.